SC Series

Features

- It is a non-resettable thermal link that uses a fusible alloy for its thermal element.

- To use ceramic container improves its thermal sensitivity.

- To use tin plated iron wire improves soldering heat resistance. It suitable for flow soldering.

- It is compliant with RoHS2.

- Extremely simple construction ensures reliability, and hermetically sealed thermal element reduces deterioration with age.

- It has superior thermal sensitivity.

- It uses an insulating container.

- Please feel free to ask us about cutting, forming, and taping of lead wire.

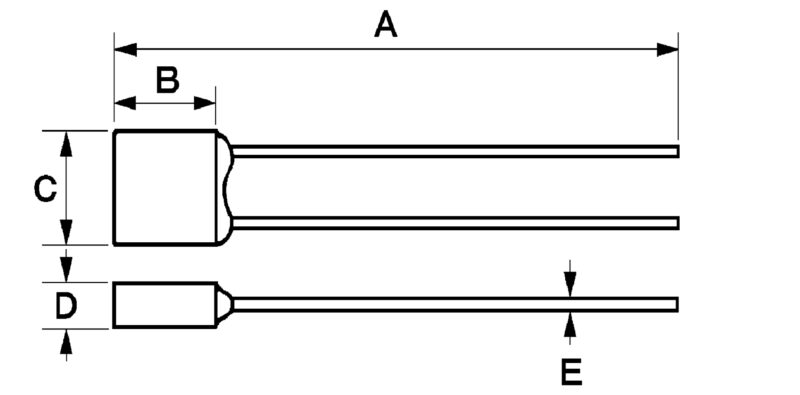

| Lead length | Dimensions (mm) | ||||

|---|---|---|---|---|---|

| A | B | C | D | E | |

| Regular | 55±3 | 4.0±0.5 | 5.2±0.5 | 2.2±0.3 | 0.53±0.02 |

Specification

| Type No. | Rated functioning temperature Tf (℃) | Functioning temperature (℃) |

Holding temperature Th (℃) | Maximum use temperature (℃) | Maximum temperature limitTm (℃) | Electrical rating | |

|---|---|---|---|---|---|---|---|

| Ampere (A) |

Voltage (V) |

||||||

| SC2 | 115 | 112±3 | 95 | 89 | 200 | 1 | AC250 |

| 58 | 52 | 3 | DC50 | ||||

Safety standard information

| Type No. | Safety standard approval | |||||

|---|---|---|---|---|---|---|

| PSE | UL | C-UL | VDE | CCC | KC | |

| SC2 | JET5267-32001-1004 (AC250V) |

E50082 | - | 40027707 | 2020980205000090 (AC250V) |

- |

- Functioning temperature is measured with silicone oil bath of which temperature is increased at the rate of 1℃/min. Detecting current is 0.1A or less.

- Please feel free to contact us in regard of the details of safety standard approvals.

Application guidance

- ELCUT THERMAL LINKS INSTRUCTION MANUAL

- About Thermal links

- Types and Characteristics of Thermal links

- Performance of Thermal links

- Utilization Technology

- Technology Trends

- Thermal links ( Caution)

- Thermal links ( Caution to be observed when designing for use of thermal links)

- Thermal links ( Caution to be observed when installing thermal links)

- Thermal links (Other caution)